Industries

Railways

We perform work for European railway manufacturers and supply companies

Renewable energies

We a trusted partner for a variety of European manufacturers in the industry

Telecommunications

We provide solutions for the main network operators

Industry

We respond to multiple sectors such as construction or equipment and machinery production

Automotive

Our products set us apart in this strategic industry

Mobility

We promote a more efficient and connected future through sustainable and tailored solutions

Shipbuilding

We participate in the design, development, and fabrication of shipbuilding elements for onboard living

Street furniture

We design, adapt, and manufacture customized solutions, based on in-depth study of the location and its surroundings

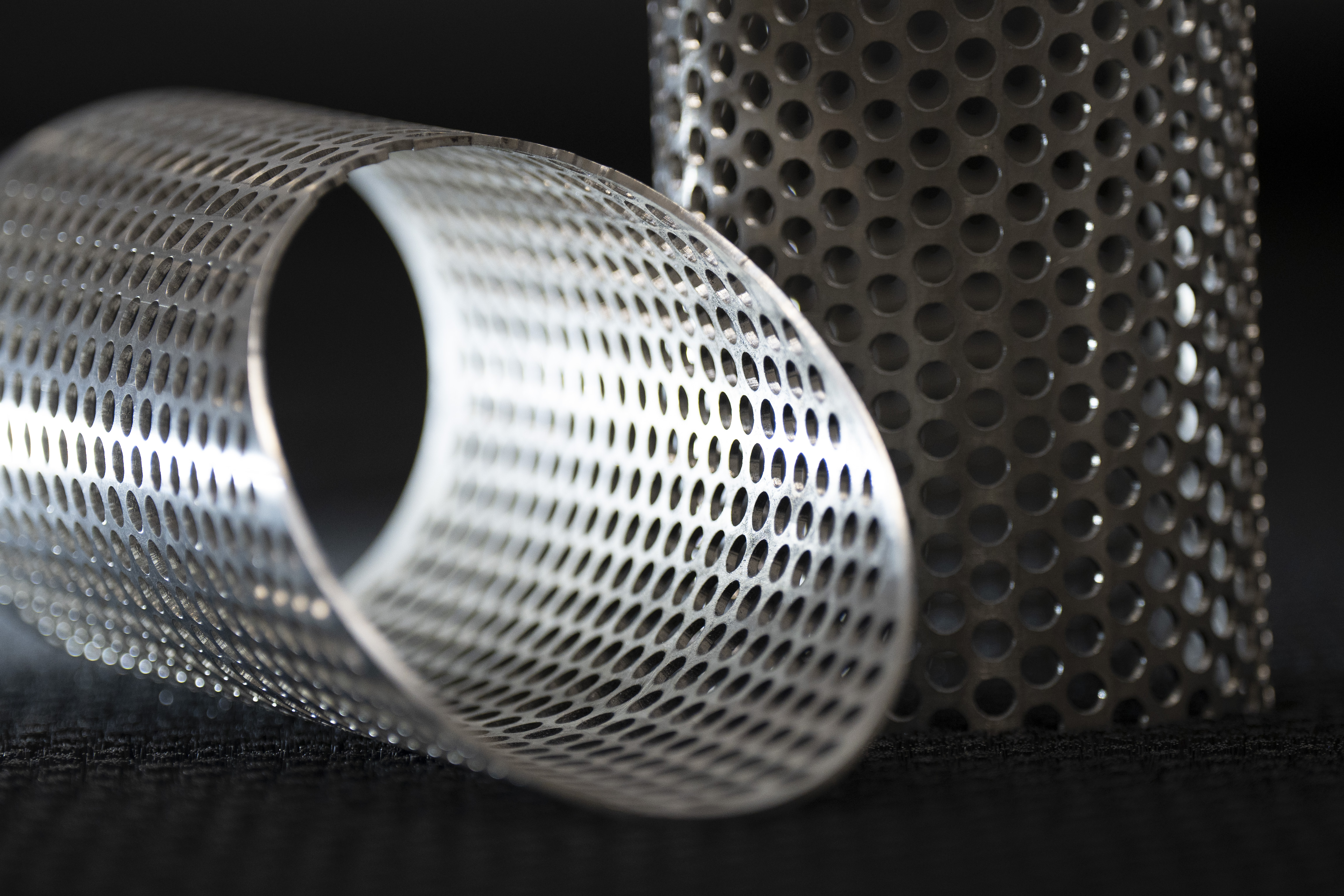

Solutions and processes

Advanced logistics

We apply technological advancements to all of our processes. By taking advantage of the latest Industry 4.0 developments, we have been able to implement leading-edge warehouse logistics, in order to achieve more efficient cutting operations and generate synergies in our processes throughout the entire supply chain.

More information

Gamelsa

Specialists in end-to-end metal solutions

Gamelsa is synonymous with technology applied to metallurgy. We are constantly dedicated to the spirit of innovation, so that we can always incorporate the latest technologies into our design and fabrication processes for metal structures, especially those that incorporate electronic elements. This is our passion.

Technology as a quality guarantee

The use of advanced technologies is the common thread that unites all of the companies belonging to the Televes Corporation. This means that at Gamelsa, we do more than just design and fabricate metal parts. We also look for ways to provide added value for our customers, by applying the latest technologies to our metallurgical processes.

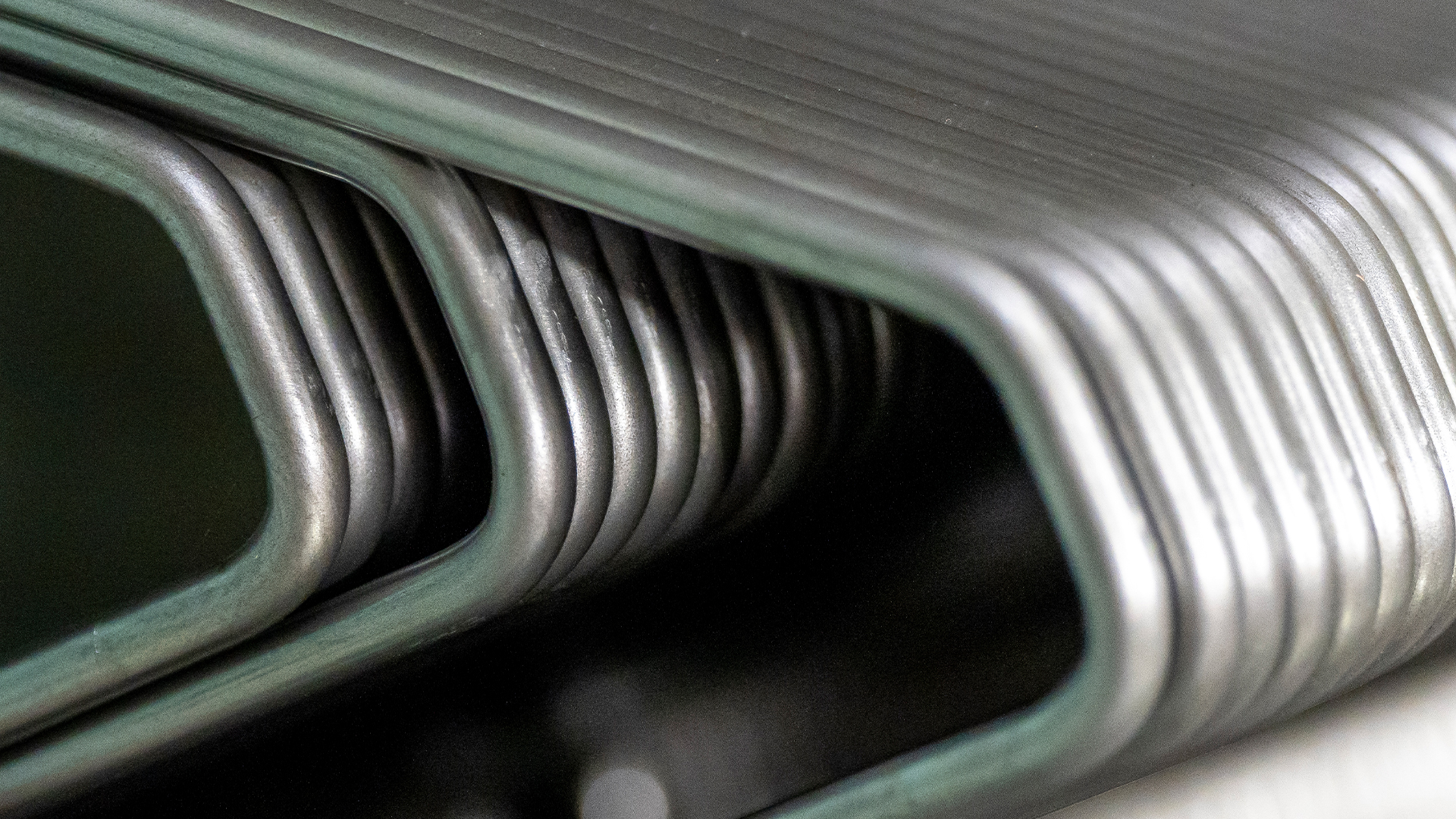

Advanced industrial automation

Our success is based on the impact achieved by automating our processes. Increased productivity, quality, and efficiency, together with constant improvement of our production processes and working conditions, are the benefits we achieve through ongoing industrial investment, which also allows us to generate more competitive offers.

Technical knowledge tailored to clients

Gamelsa employs highly qualified technical personnel, and our technical office has expertise in optimizing our customers’ designs, by adapting them to our production processes in the most efficient way.

Guaranteed quality and service

Technology, investment, and technical qualifications are all factors that support our guarantees and customer service, and this is also demonstrated by our possession of the main industry certifications

Management System Certificates

View moreExecution of steel structures and aluminum structures